GLP-1-beskyttet aminosyre til sidekædemodifikation

Produktdetaljer

| INGEN. | Produkter | CAS-nr. | Anvendelse | Nøglekvalitetsindikator | ||||

| Renhed | Isomer | SI * | Maks. * | Fugtighed | ||||

| 1 | Fmoc-Lys(Mtt)-OH | 167393-62-6 | Modifikation af lysin-sidekæden | ≥99,0% | ≤0,1% | ≤0,2% | ≤0,3% | ≤1,0% |

| 2 | Fmoc-Lys(Alloc)-OH | 146982-27-6 | Modifikation af lysin-sidekæden | ≥99,5% | ≤0,1% | ≤0,1% | ≤0,2% | ≤1,0% |

| 3 | Fmoc-Lys(ivDde)-OH | 150629-67-7 | Modifikation af lysin-sidekæden | ≥98,0% | ≤0,2% | ≤0,3% | ≤0,5% | ≤1,0% |

| 4 | Fmoc-Lys(Mmt)-OH | 159857-60-0 | Modifikation af lysin-sidekæden | ≥98,0% | ≤0,2% | ≤0,3% | ≤0,5% | ≤1,0% |

| 5 | Fmoc-Glu-OtBu | 84793-07-7 | LiraglutidSemaglutid | ≥99,5% | ≤0,1% | ≤0,1% | ≤0,2% | ≤1,0% |

| 6 | Glu-OtBu | 45120-30-7 | LiraglutidSemaglutid | ≥99,5% | ≤0,1% | ≤0,1% | ≤0,2% | ≤1,0% |

| 7 | Octadecandisyre | 871-70-5 | Semaglutid | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 8 | Octadecandisyremono-tert-butylester | 843666-40-0 | Semaglutid | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 9 | tBu-OOC-C16-CO-Glu-OtBu | 1188328-39-3 | SemaglutidFragment A | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 10 | AEEA | 134978-97-5 | SemaglutidAlbuvirtid | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 11 | AEEA-OH.HCl | 134979-01-4 | SemaglutidAlbuvirtid | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

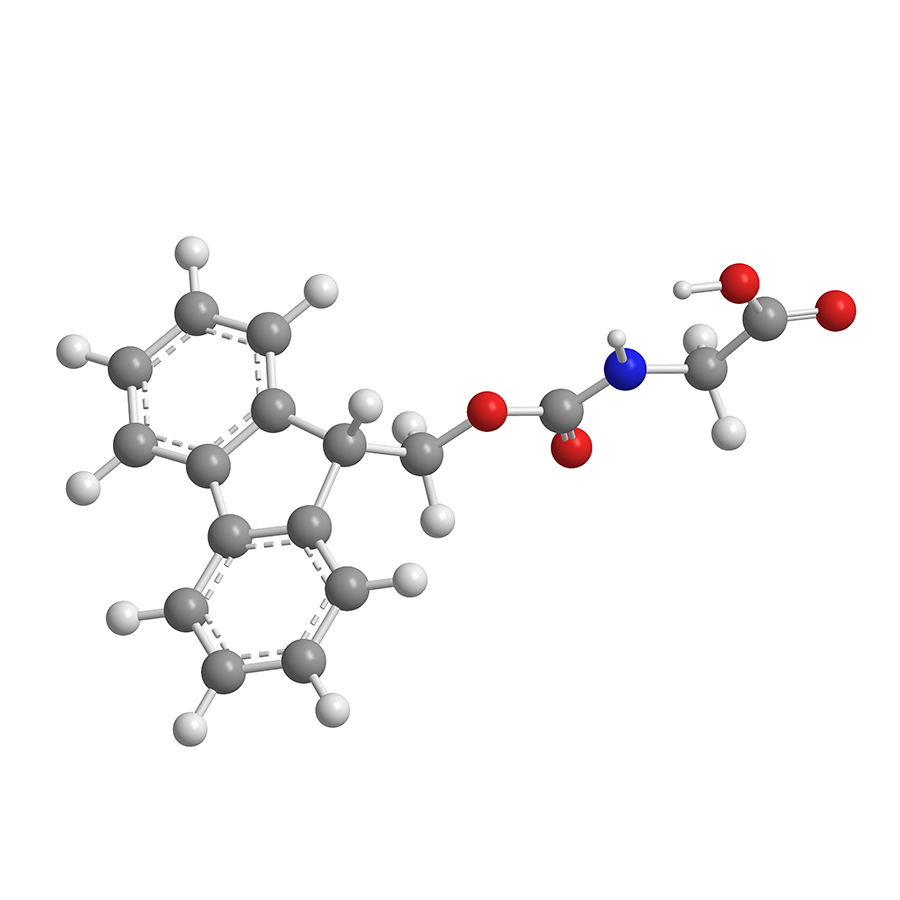

| 12 | Fmoc-AEEA-OH | 166108-71-0 | SemaglutidAlbuvirtid | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 13 | Boc-AEEA-OH | 108466-89-3 | Semaglutid | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 14 | AEEA-AEEA | 1143516-05-5 | Semaglutid | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 15 | Fmoc-AEEA-AEEA-OH | 560088-89-3 | SemaglutidFragment B | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 16 | Octa(OtBu)-Glu(ɑ-OtBu)-AEEA-AEEA-OH | 1118767-16-0 | SemaglutidFragment C | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 17 | tBu-OOC-C16-CO-Glu(AEEA-AEEA-NHS)-OtBu | 1118767-15-9 | SemaglutidFragment D | ≥96,0% | ≤0,5% | ≤1,0% | ≤1,0% | ≤1,0% |

| 18 | Fmoc-Lys(tBu-OOC-C16-CO-Glu(AEEA-AEEA)-OtBu)-OH | 1662688-20-1 | Semaglutidfragment E | ≥96,0% | ≤0,5% | ≤1,0% | ≤1,0% | ≤1,0% |

| 19 | Boc-His(Trt)-OH | 32926-43-5 | Enden er histidin | ≥99,5% | ≤0,1% | ≤0,1% | ≤0,2% | ≤4,0% |

| 20 | Fmoc-Aib-OH | 94744-50-0 | Semaglutid | ≥99,5% | / | ≤0,1% | ≤0,2% | ≤1,0% |

| 21 | Boc-His(Trt)-Aib-OH | 2061897-68-3 | Semaglutid | ≥99,0% | ≤0,1% | ≤0,2% | ≤0,3% | ≤2,0% |

| 22 | Fmoc-Glu(OtBu)-Gly-OH | 866044-63-5 | GLP-1-analog | ≥99,5% | ≤0,1% | ≤0,2% | ≤0,2% | ≤1,0% |

| 23 | Boc-His(Trt)-Aib-Glu(OtBu)-Gly-OH | 1169630-31-2? | Semaglutidfragment F | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 24 | Boc-His(Trt)-Aib-Glu(OtBu)-Gly-NHS | 1169630-40-3 | Semaglutidfragment G | ≥96,0% | ≤0,5% | ≤1,0% | ≤1,0% | ≤1,0% |

| 25 | Fmoc-Arg(pbf)-Gly-OH | 660846-80-0 | GLP-1-analog | ≥99,5% | ≤0,1% | ≤0,2% | ≤0,2% | ≤1,0% |

| 26 | Fmoc-Ala-Ala-OH | 87512-31-0 | GLP-1-analog | ≥99,5% | ≤0,1% | ≤0,2% | ≤0,2% | ≤1,0% |

| 27 | Fmoc-Thr(tBu)-Phe-OH | 1260609-75-3 ? | GLP-1-analog | ≥99,5% | ≤0,1% | ≤0,2% | ≤0,2% | ≤1,0% |

| 28 | Palmitinsyre | 1957/10/3 | Liraglutidfragment 1 | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 29 | Palm-Glu-OtBu | NA | Liraglutidfragment 2 | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 30 | Palm-Glu(NES)-OtBu | NA | Liraglutidfragment 3 | ≥96,0% | ≤0,5% | ≤1,0% | ≤1,0% | ≤1,0% |

| 31 | Fmoc-Lys(Palm-Glu-OtBu)-OH | 1491158-62-3 | Liraglutid | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 32 | Hexadecandisyre | 505-54-4 | Insulin degludec | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 33 | Hexadecandisyremono-tert-butylester | 843666-27-3 | Insulin degludec | ≥99,0% | / | ≤0,2% | ≤0,3% | ≤1,0% |

| 34 | tBu-OOC-C14-CO-Glu-OtBu | NA | Insulin degludec Fragment I | ≥98,0% | ≤0,2% | ≤0,5% | ≤0,5% | ≤1,0% |

| 35 | tBu-OOC-C14-CO-Glu(NES)-OtBu | NA | Insulin degludec Fragment II | ≥96,0% | ≤0,5% | ≤1,0% | ≤1,0% | ≤1,0% |

SI *= Specifik urenhed

Maks*= Maks. ukendt urenhed

Anden indikator:

- Eddikesyre: ≤0,02% (Alle produkter)

- Ethylacetat: ≤0,5% (alle produkter)

- Alkohol: ≤0,5% (alle produkter)

Desinficering

Sanering af distributionssystemet, inklusive sløjfe og lagertank, udføres ved pasteurisering. Når pasteurisering udføres, opvarmes det rensede vand i tanken til 80 °C og begynder at cirkulere gennem distributionssystemet. Saneringen varer 1 time efter at have nået 80 °C. Sanering udføres hvert kvartal. Saneringslogbogen for det rensede vandsystem blev kontrolleret uden markering af afvigelser.